Modular Vice/Vise Manufacturers, Dealers, Suppliers in Odisha

Welcome to Sai Truman Enterprises Enterprises, the leading Modular Vice/Vise dealers, manufacturers, suppliers, distributors, stockiest, traders in Odisha, Bhubaneshwar, Cuttack, Brahmapur, Raurkela, Sambalpur. Explore our extensive range of modular vices in Odisha, Bhubaneshwar, Cuttack, Brahmapur, Raurkela, Sambalpur designed to elevate your machining experience. Our innovative designs ensure superior clamping, flexibility, and efficiency, catering to the evolving needs of modern manufacturing.

Crafted with precision and engineered for excellence, our modular vice/vise empowers you to optimize your workflow and achieve unparalleled accuracy in every project. Trust Sai Truman Enterprises for state-of-the-art modular vices that redefine precision in machining.

Introduction

Modular vises are essential tools in machining and manufacturing, offering flexibility, precision, and efficiency in clamping workpieces securely during various machining operations.

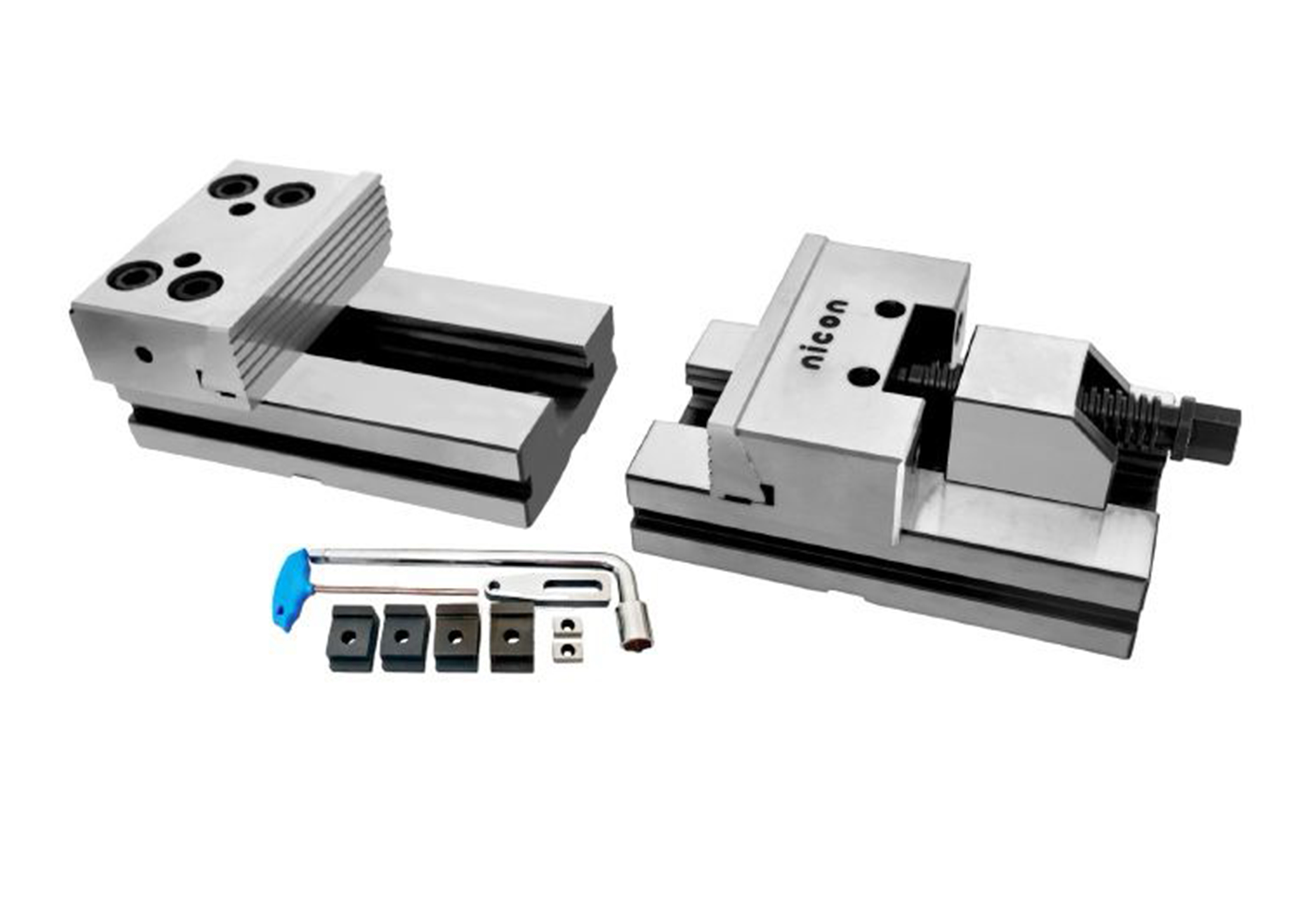

Our Modular vices are characterized by their modular design, which allows for adaptability to different workpieces and machining requirements. Typically made from high-quality materials such as hardened steel or aluminum, these vices feature robust construction to withstand the rigors of industrial use.

They often incorporate a modular jaw system, enabling the quick and easy customization of jaws to accommodate diverse workpiece shapes and sizes. Some modular vices also come equipped with features like precision-ground surfaces and adjustable clamping mechanisms for enhanced accuracy.

| Features | Description |

| Design | A modular vice that is commonly used with CNC milling machines for precise milling and grinding. |

| Clamping Mechanism | For accurate and secure clamping, the workpiece must run down against the vice base since both jaw plates are at a pull-down angle. |

| Exchangeable Components | The vice's interchangeable parts offer a variety of workholding options with precise alignment |

| Space-saving Design | The maximum blocking ratio to the vice's overall dimension is made possible by the strong construction and space-saving design. |

| Improved Capacity | When utilizing jaw extensions, the maximum opening capacity is increased by four additional tapped holes with a ground back jaw rear face. |

| Material | HRC 60 ±2 case-hardened resistant steel with high alloy quality that offers little wear, maximum rigidity, and excellent performance. |

Get Best Quote From Sai Truman Enterprises

Modular Vices

- HRC 60 ±2 case-hardened resistant steel with high alloy quality that offers little wear, maximum rigidity, and excellent performance.

Advantages

The key advantages of modular vices make them indispensable in machining setups: -

- Versatility: The modular design allows for quick adjustments and customization, making these vices suitable for a wide range of workpiece geometries and sizes.

- Precision Clamping: With precision-ground surfaces and adjustable components, modular vices provide high levels of accuracy in securing workpieces, ensuring consistent and reliable results.

- Time Efficiency: Quick and easy adjustments facilitate rapid setup changes, reducing downtime between machining operations and improving overall production efficiency.

- Cost-Effective: The adaptability of modular vices eliminates the need for multiple dedicated fixtures, saving costs associated with purchasing and maintaining different clamping devices for various workpieces.

Industries we serve: -

Modular vices find application in diverse industries and machining processes: -

- CNC Machining: Ideal for CNC machining centers, modular vices securely hold workpieces during milling, drilling, and other precision operations.

- Tool and Die Making: In the production of molds and dies, modular vices accommodate the varying shapes and sizes of workpieces, ensuring precise and repeatable clamping.

- General Machining: Whether in a milling machine or on a workbench, modular vices are versatile tools for holding components during tasks such as milling, shaping, or grinding.

- Prototyping and Small-Batch Production: The adaptability of modular vices makes them well-suited for prototype development and small-batch production, where frequent setup changes are common.